Last Updated on: 7th May 2023, 11:49 am

There’s always a positive difference between a plain fake ID card and a laminated ID card, with the laminated one being the better option. While it may seem like laminating ID cards is a complicated and torturous process, this is not the case. All that’s needed are the suitable materials and knowledge of the proper techniques for various ID card types. There’s a need to understand the importance of lamination before delving into how to laminate ID cards.

Why Do We Laminate Fake IDs?

At the center of curbing the rising insecurities is lamination printing technology for ID cards. This simple card system allows companies to create a secure way of identifying their employees but also protects them from embarrassment.

Laminating ID card printer technology uses a simple technique that adds an opaque protective layer of polyester film on top of the details written on a small piece of paper. Card lamination is also referred to as lamination card printers. It is a printing machine that automatically adds this thin layer, giving it a professional look.

While laminated ID cards have continued to grow in popularity, there’s still a need to highlight the significant reasons why laminating ID cards is the way to go. Fake ids loaded with laminated holograms are as real as ids issued by state DMV & they are only used by the best fake id websites. The rolls that are available online are of inferior quality and lack clarity which is required for making scannable ids.

Process of Laminating ID Cards in the Past

A little science and some bravery are much like it, but the process was called the film-based method, or cut and paste. Now, these two depend on the type of ID cards laminated. Any type of ID card can be laminated to keep them safer, durable, and away from wear and fading. Over the years, the process of laminating ID cards has come a long way and can be done in various ways.

For example, if the ID card already had all the details and pictures on it, it was placed between two film sheets a little wider in dimension than the card itself, in between two sheets of paper, and passed between two heated rollers to create a firm seal. The cut and paste method was for ID cards that did not have the photo attached to them.

The technician will cut the photo to size, attach it to the ID card, add the laminate sheet and pass it through the heated rollers. This process was inexpensive but took an awful lot of time to issue plenty of top fake ids at a go. Additionally, it was not secure as the laminate film would peel off with constant touch or become brittle and start to break off.

1. Laminates Help Fake IDs Scan

ID cards usually have a standard thickness of 30 mils. However, the extra laminated layer increases this by at least 5 mils. A standard ID card which is about 25% thicker, is an excellent choice because this provides an extra layer of protection for your card. It is less susceptible to cracking, bending and other physical damage.

This is also a great way to keep the surface of your cards free from the negative impact of dust, dirt, water and other debris. The increased durability means you don’t have to worry about replacing the ID cards every other month. Without the impact of a scannable laminate; fake ids will not absorb the magnetic stripe or QR codes on the backside. Hence, any counterfeit id without a premium laminate roll can never scan.

2. Laminated IDs Can Pass Visual Inspection

While the primary purpose of an ID card is for identification, it also serves the dual purpose of projecting professionalism. A laminated fake ID card will do this perfectly, and we all know how first impressions are great in any setting. In addition, a crisp and clean-looking laminated ID card will ensure a consistently professional outlook and pass under the scrutiny of a trained bartender or doorman.

Laminating Techniques & Equipment Used by Counterfeit Industry

Types of Machines

Laminating machines usually apply two methods – hot or cold, but the hot laminating equipment is the most common.

1. Thermal Laminating Machines

This type of laminator uses two sheets of plastic film sealed at one edge. The ID card to be laminated is placed in the appropriately sized pouches, trimmed, and passed through a hot roller. Once the sheet passes through the rollers, the opaqueness of the sheet disappears and becomes transparent as the adhesive between the sheets sticks to the card and binds it firmly.

2. Non-Thermal Machines

ID cards or printed cards that are heat sensitive employ this laminating technique. Cold lamination, unlike hot lamination, uses pressure to activate the adhesive in the plastic film that adheres to the card. While both methods protect the ID cards, hot lamination produces better & finer images and texts and more secure cards than cold lamination.

So, what are the top laminating techniques? Three major ones have become popular in this industry over the last few years.

1. How do we Laminate Teslin IDs?

Using the correct laminating technique on your ID card material is one of the most critical aspects of the lamination process. For Teslin paper, the right choice is a butterfly pouch for lamination. Teslin Paper is accepted in most places worldwide for use on professional ID cards. However, printing on this material is not as complicated as it may sound. With most states opting for real ID compliant ids, Teslin is no longer used by the state DMV for printing identification cards. There are still a handful of states using Teslin for issuing driving licenses which makes it relevant in 2022.

Teslin Compatible Equipment

You can print on Teslin paper using a laser or inkjet printer. As there are laser Teslin and Inkjet Teslin, you should pay more attention to picking the Teslin sheet that is fitted for your printer. Usually, these sheets are perforated in specific areas to enable you to remove the ID card insert easily after printing.

The next stage is the laminating pouch, where a butterfly pouch comes in. This is the best choice for Teslin paper as the output is an edgeless ID card perfect for its purpose. While regular laminate pouches leave one edge with excess laminate, the butterfly pouches use a single piece of laminate with a score line that gives room for folding and allows the Teslin paper surface to bond smoothly, forming a solid borderless card. In addition, this technique is affordable since it eliminates the need for a special ID card printer.

So, what thickness of butterfly pouches is best for Teslin sheets? Usually, a credit card ranges from 26 to 30 mils in thickness. A mil is equivalent to 0.001 inches, and the thickness of a pouch is advertised for just one side. Therefore, for a 10 mil Teslin on a 7 mil laminate, the result will be an ID card that’s 24 mils thick.

2. How do we Laminate Polycarbonate IDs?

Another popular plastic lamination technique in existence is polycarbonate lamination. Lamination is one of the best methods for making more functional polycarbonate sheets. This involves bonding layers of a polycarbonate sheet together, and this crucial process becomes successful with suitable materials.

Depending on the type of laminate used, you could opt for lamination through adhesives or heating. Laminating polycarbonate is vital for several reasons, and here are a few:

- Most times, you would need the final product to have specific properties. These include anti-scratch, anti-reflection or anti-glare. So, how do you go about this?

- It’s not an easy task to incorporate these properties into a finished product, but lamination makes it a tad less complicated.

- Lamination is also one of the best ways to make polycarbonate fake ids resistant to creases.

- However, you have to pay attention to the base materials to ensure they are suitable before the final lamination process.

- Polycarbonate license is also great for making the finished id look as real as possible.

- It’s no secret that laminated polycarbonate materials look more appealing than their plain outlook before lamination.

Another not-so-common advantage of laminating polycarbonate materials is that it provides a protective layer on the material, increasing the chances of clarity in diverse conditions. This applies to the windscreen of a vehicle during adverse weather conditions where lamination prevents it from scratching and protects it from glares that would reduce visibility.

Popular Techniques For Laminating Polycarbonate IDs

Now that we’ve established the various applications of laminated polycarbonate ids, let’s talk about the different techniques available. Two major polycarbonate laminating techniques are available, and their application depends on your preferred result. These are:

1. Resin Polycarbonate Laminates

This process involves the lamination of polycarbonate using a resin. Resin is a semi-viscous substance found in plants, and you can convert this into polymers. When polycarbonate is laminated using resin, this substance has a powerful adhesive that holds the material together into the desired shape.

The excellent viscosity of resin makes it easy to use and is also an affordable lamination method. For this, you don’t need to purchase expensive machines; this type of lamination protects the polycarbonate from the effects of bad weather.

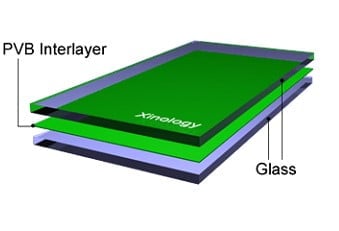

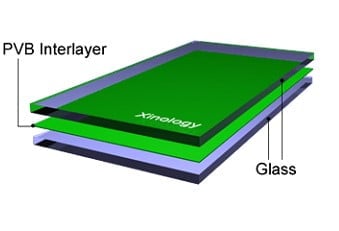

2. Polyvinyl butyl (PVB) Lamination

Many people in the laminating industry would instead opt for polyvinyl butyl (PVB) polycarbonate lamination, and it’s not difficult to see why. It’s the preferred choice for applications that require strong adhesion to various surfaces, toughness with a mix of flexibility, and optical clarity.

PVB polycarbonate lamination usually involves bonding two or more sheets together using a layer of PVB or as many layers as necessary. However, you would need more sophisticated machinery for this process as it requires nip rollers to expel air bubbles, unlike resin lamination, which does this automatically. In addition, the interlayer performs binding roles and is viscoelastic.

3. PVC Lamination

This type of lamination requires a specific ID card printer where the lamination process involves heat and pressure application after printing the card design. Here, a laminate film is needed to serve as a barrier against color fading, abrasion and other factors. The laminating ID card printers come in handy here as they apply the laminate through a fast two-step process.

Types of Fake ID Lamination Finishes

There are three lamination types, and each has its benefits and finishes for the ID.

1. Matte ID Laminates

This is a common lamination technique that gives the fake ID card a smooth and clear matte finish. It also makes the printed text and photo look brighter and easier to read, and less light reflection. The ID card looks natural, sophisticated, and secure.

2. Gloss ID Laminates

This is another lamination style that uses a plastic sheet and produces a smooth and shiny finish. It is applied on both sides of the ID cards to give them a high-quality look and protection from wear and fading.

3. Soft Touch ID Laminates

This is a luxurious style that gives a luxurious finish to the ID card. It is almost like a matte finish but offers a velvety finish to the ID cards. They are equally secure and protect the card for a long time.

This is a common lamination technique that gives the ID card a smooth and clear matte finish. It also makes the printed text and photo look brighter and easier to read, and less light reflection. The ID card looks natural, sophisticated, and secure.

Conclusion

A regular laminated PVC ID card is not durable, but using a high-quality card material like PVC + PET will increase the durability and strength of the card and lower the cost. This is one area companies are not willing to readily invest in. The Polycarbonate counterfeit id is a better alternative when laminated, and the card printer is affordable and requires less maintenance. Another advantage between Teslin and PVC laminated ID cards is the size. The regular PVC lamination printer allows cards in one size, but Polycarbonate and Teslin offers different sizes.

Depending on the printer’s capability, the process starts with a clear film, and the built-in lamination module uses high temperatures to carry out the lamination. Undoubtedly, investing in the right materials and equipment will ensure that the lamination process is smoother than ever.

Inspected your Massachusetts laminate. The thickness is 6 mils per flap. While the DMV ones are around 7 mils. That is not much of a difference in terms of visual id checking. New apps such as Show-me ID will catch counterfeit ids inspecting these little flaws. The likes of IDgod & other vendors who use cheaper quality of laminates (mainly sold on Alibaba) are crap. They are not clear after thermal laminating and lack rounded corners